Your Cart is Empty

Ring Chuck Only - for SSRT (slow speed ring turner)

$3.50 USD

*THIS LISTING IS FOR THOSE WHO ALREADY OWN A SLOW SPEED RING TURNER*

OPTIONS:

CHUCK = THE ENTIRE CHUCK ASSEMBLY - RECOMMENDED FOR USE WITH THE SLOW SPEED RING TURNER.

PRONGS <NO HARDWARE> = REPLACEMENT PRONGS WITH NO HARDWARE

PRONGS WITH HARDWARE = REPLACEMENT PRONGS WITH HARDWARE

*WARNING

This equipment was made solely for use with my Slow Speed Ring Turner

Use for other purposes is not recommended and you do so at your own risk.

This listing is for Only the ring chuck. Nothing else shown will be shipped.

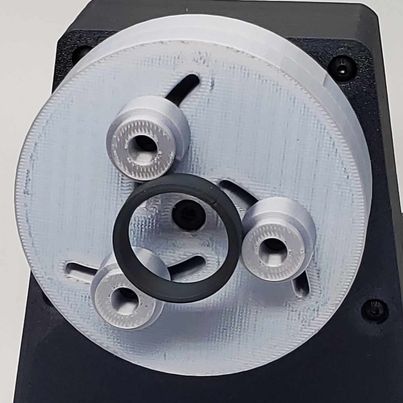

Self Centering, Adjustable Chuck for use with our SSRT (Slow Speed Ring Turner)

The adaptor slides over the 7mm motor shaft and attaches via 2 grub screws.

Ideal for applying UV resin finish.

If applying CA Glue finish, please wrap the prongs with teflon tape or some other glue resistant tape.

I'm working on making glue resistant prongs.

-----------------------------------------

Chuck Operation:

The Chuck attaches to the motor shaft via grub screws. Seat them and the chuck should stay put and remain centered.

The chuck consists of several parts, primarily 2 plates. To actuate the chuck (move the pins) twist the plates opposite of each other.

Use this motion to grab whatever you want to hold with the pins (your ring) it may take some practice to get the hang of it but you'll be applying finish to the insides of your rings like a pro in no time.

If you're not getting a tight hold, you can tighten the center screw in the middle of the plates by a quarter of a turn. This should help but if it doesn't, turn your attention to the back of the chuck. Tighten the wingnuts a bit (if you have spacers under the wing-nuts, tighten those a touch. You want to increase the overall friction so that when you tighten around a ring it won't loosen on its own.

In the event that there's a bind in the chuck's motion, check the following items:

Make sure the wing-nuts on the back are finger-tight.

If there's a spacer under the wing-nut (later versions) make sure it's not too tight. You can loosen it to reduce the friction of the mechanism. (Alternatively you can tighten them to increase the friction. )

Make sure there's no obstructions in the pathways.

OPTIONS:

CHUCK = THE ENTIRE CHUCK ASSEMBLY - RECOMMENDED FOR USE WITH THE SLOW SPEED RING TURNER.

PRONGS <NO HARDWARE> = REPLACEMENT PRONGS WITH NO HARDWARE

PRONGS WITH HARDWARE = REPLACEMENT PRONGS WITH HARDWARE

*WARNING

This equipment was made solely for use with my Slow Speed Ring Turner

Use for other purposes is not recommended and you do so at your own risk.

This listing is for Only the ring chuck. Nothing else shown will be shipped.

Self Centering, Adjustable Chuck for use with our SSRT (Slow Speed Ring Turner)

The adaptor slides over the 7mm motor shaft and attaches via 2 grub screws.

Ideal for applying UV resin finish.

If applying CA Glue finish, please wrap the prongs with teflon tape or some other glue resistant tape.

I'm working on making glue resistant prongs.

-----------------------------------------

Chuck Operation:

The Chuck attaches to the motor shaft via grub screws. Seat them and the chuck should stay put and remain centered.

The chuck consists of several parts, primarily 2 plates. To actuate the chuck (move the pins) twist the plates opposite of each other.

Use this motion to grab whatever you want to hold with the pins (your ring) it may take some practice to get the hang of it but you'll be applying finish to the insides of your rings like a pro in no time.

If you're not getting a tight hold, you can tighten the center screw in the middle of the plates by a quarter of a turn. This should help but if it doesn't, turn your attention to the back of the chuck. Tighten the wingnuts a bit (if you have spacers under the wing-nuts, tighten those a touch. You want to increase the overall friction so that when you tighten around a ring it won't loosen on its own.

In the event that there's a bind in the chuck's motion, check the following items:

Make sure the wing-nuts on the back are finger-tight.

If there's a spacer under the wing-nut (later versions) make sure it's not too tight. You can loosen it to reduce the friction of the mechanism. (Alternatively you can tighten them to increase the friction. )

Make sure there's no obstructions in the pathways.